In monstrare monstrare in mechanica intricatam, ubi reliability et praecisione sunt paramunt, stampam circlips - etiam quae Stamped retinendi annulos Aut Snap Annulorum - Planta Planta Sed saepe underappreciated munus. Haec parva, circularis fasteners, typically fabrica a tenuis metallum rudentis uti summus praecisione techniques, quae disposito secure components onto sagittas vel in housings filate fallen aut in tibia aut in treaded filate aut in treaded flats aut in treads aut in treads flaturnes aut in treads aut in treads flaturnens aut complexu machining.

Dissimilis eorum filum-formatae counterparts, quae sunt tetendit in figura, stamping circlips formatae per frigus-formatam processus, quod concedit pro maius designs flexibilitate, tolerantia, et amplificata onus-ferre. Quorum facultatem esse massa, produci ad humilis sumptus dum maintaining structural integritas fecit eos necessaria contra Automotive, Aerospace, Industrial Machinery et Consumer Electronics Sectores.

Hoc articulum explorat vestibulum principiis, eget commoda, materia considerationes, et expanding applications de Stampclips, excitatur eorum crescente momenti in modern mechanica systems.

Vestibulum processus structural consilium

Stamping CIRCELIPS sunt produci per progressivum mori stamping technology, in quo plana sheet metallum pascitur per seriem Tooling stationibus, quod Conscidisti, forma et figura in ultima pars cum alta repeatability. Hoc modum dat artifices ad producendum millia identical partibus per hora dum maintaining stricta dimensiva potestate.

Key Design features includit:

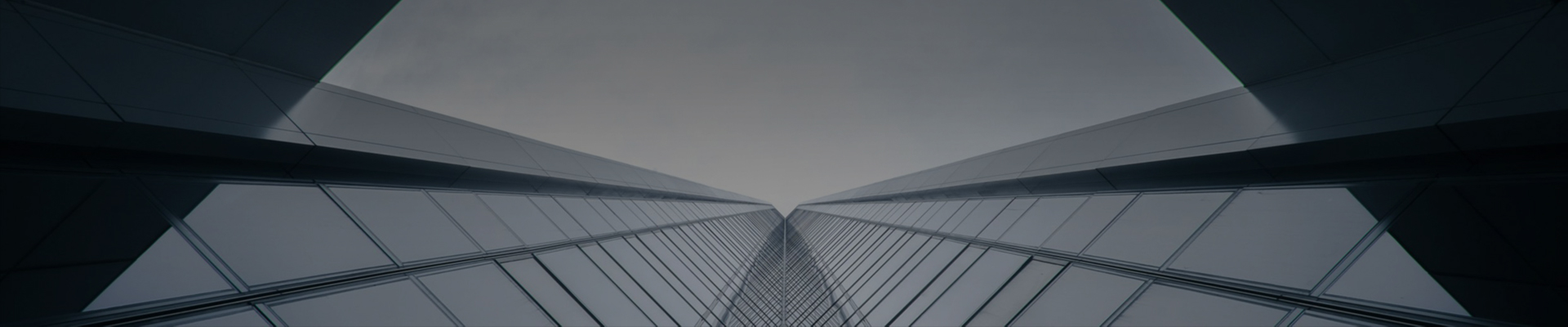

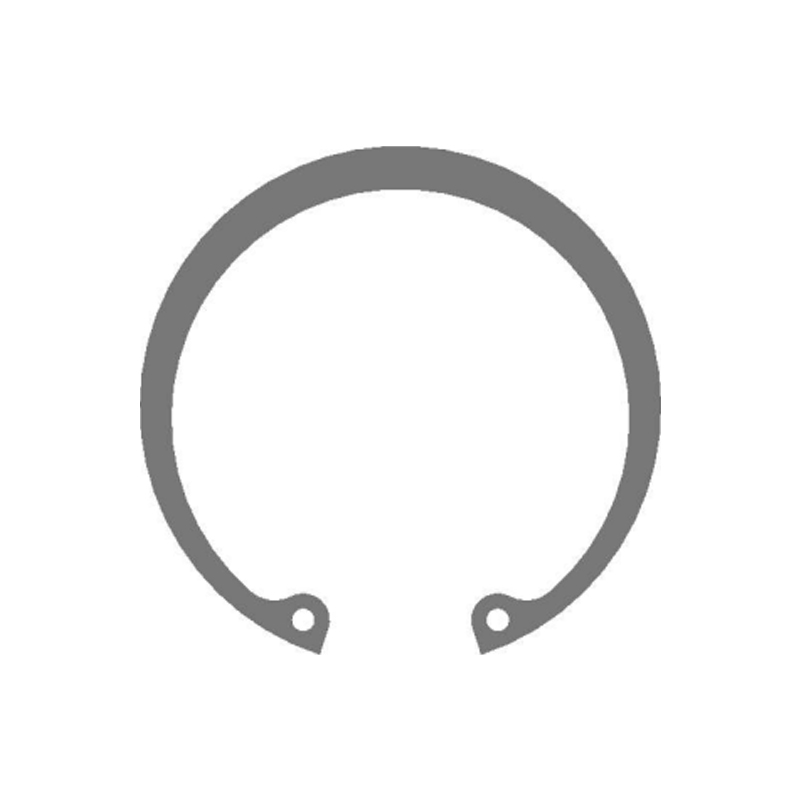

Segmented aut plenus-circulus configurations: fretus in applicationem, CIRCELIPS potest habere aperta gap ad institutionem aut plenum CCCLX-gradu anulum cum split enim compressionem conveniens.

Internum seu externa retention profiles: Internum CIRCELIPS fit in striatus intra beram, cum externa genera sedent in hastile retinere components.

Retention tabs aut lugs: Quidam Designs incorporate parva protrusions vel foramina, quae patitur ad facile remotionem usura specialized pii vel tools.

Superficies treatments: options ut cadmiae plating, phosphate coating, aut nigrum cadmiae augendae corrosio resistentia et redigendum friction durante installation.

Integration in compagine constructione concedit in compagine conventiones in coetu coetibus, ubi spatio tollatur, ut traditional fasteners impossibiles.

Eget commoda in alternative retinendi modi

Comparari ad alias assidua solutions ut filaque nuces, adhesives, aut filum CIRCELIPS, Stamping CIRCELIPS offer aliquot distincta beneficia:

Productio sumptus-effective productionem: et summus celeritas Stamping processus significantly reduces unit costs, praesertim in magna-volumine productio fugit.

Tractus Efficens: disposito ad operari in minimam axial spatio, faciens ea specimen ad miniaturized vel densely facis conventibus.

Otium of installation et remotionem: dissimilis stila fasteners, non requirere non tensis torque et potest installed celeriter per automated feeders et manual instrumenta.

Maximum onus capacitatem, cum bene sedet in machined sulcus, haec annulos providere reliable axial retention etiam sub dynamic loading condiciones.

Vibrationis resistentia: et radia tenaci de insignitur profile adjuvat ponere positus in ambitum prone ad mechanica inpulsa seu oscillationis.

Hae commoda et Stamping Circlips praecipue valuable in applications ubi disassembly requiritur ad sustentationem vel reparatione.

Material Electio et perficientur considerations

Material electionis ludit in Pivotal partes in determinandum perficientur characteres de Stamping Circlips. Communis Options include:

Carbon ferro: offert princeps vires et gerunt resistentia; Saepe usus est in gravibus, officium mechanica systems.

Aliquam Steel (Austenitititic aut Martensitic Grades), malle in malleos environments ut marine, eget processus, aut cibum-gradus apparatu.

Phosphor aes: lectus ad electrica conductivity et humilis-friction proprietatibus, communiter in motricium et afferentem applications.

Plated Alloys, coatings ut cadmiae, nickel, aut Chrome amplio corrosio resistentia et aesthetica in visibili components.

Utrumque materiam electionem oportet rationem factores ut operating temperatus, nuditate ad humorem vel oeconomiae, et expectata ministerium vitae.

Applications per diverse industries

Ex eorum versatility et efficientiam, stamping Circlips late adopted per multa industries:

I. Books industria

Used late in transmissiones, differentials, gubernaculo systems, et suspensionem coetus retinere gestus, anni et bushings.

II. Industrial Machinery

Integrale in Hydrau cylindrici, Gearboxes, et motor-repulsi apparatu ubi precise pars alignment et retention sunt discrimine.

III. Electronics et adjumenta

Motors usus, fans et rotating components in domum adjumenta et dolor electronics ut pacto et certa ecclesia.

IV. AEROSPACE et defensionis

Utietur in Action ratio, portum calces machinationes et Avionics modules ubi pondus reductionem et reliability sunt essentialis.

V. Medical cogitationes

In in chirurgicam instrumenta et diagnostic apparatu ubi otium of sterilization et velox disassembly magna.

Et adaptability ad utrumque static et dynamic onerat ensures continued demanda trans lata spectro mechanica systems.

Integration cum dolor vestibulum et automation

Ut vestibulum processus evolve ad maiorem automation et praecisione, stamping circlips sunt magis integrari in robotic conventus lineas et dolor ligula systems:

Automated Pascere Systems: Vibratory Pastores et Linear Track systems enable celeri, errore, liberum insertionem de CIRCELIPS in subassemblies.

Qualitas inspectionem Technologies: vision Systems et sensoriis cognoscere rectam installation et orientation in realem tempus.

Design pro manibus (DFM): Engineers Optimize Circlip Tempus Dimensiones et Material electiones mane in productum progressionem ad streamline productio et redigendum defectum metus.

Predictive Sustentacionem Integration, in altum-valorem apparatu, embedded sensoriis monitor accentus campester et gerunt patterns circa Circlip-retinuit components ad praevenirent defectis antequam fieri.

Haec progressiones conferunt ad altiorem throughput, melius reliability, et redegit downtime in profectus artifex environments.

Challenges et limitations

Quamvis sua multa beneficia, stamping circlips non universaliter applicentur. Key provocationes includit:

Sulius machining requisita: propriis munus pendent pressius machined striatus in mating hastile vel habitationi, addendo complexionem ad component consilio.

Load limitations: dum idoneam moderari axemiales, ut non praestare bene sub extrema radiales et torsional passiones.

Corrosio vulnerablity: sine propriis coatings vel materia lectio, nuditate ad humorem potest ad immatura degradation.

Installation Errores: Improprium Seating vel damnum durante installation potest compromissum retention et ducunt ad ratio defectum.

Careful ipsum et qualis imperium sunt essentialis ad ensuring diu term perficientur.

Innovations et futurum trends

Vultus praemisit, ongoing investigationis et development nisus sunt focused in meliorem efficientiam, diuturnitatem et adaptability de Stampclips:

Advanced Superficies Treatments Nano-coatings et auto-lubricating finiatur intendunt extendendi muneris vitam reducere.

Eminentive vestibulum Integration: Experimentalem usum 3D-typis tooling ad prototypum et humilis-volumen cocclip productio.

Hybrid retinendi solutions: combining tabula CIRCELING cum tenaces vinculum aut overmolding pro multi-eget in figura.

Smert Fastener concepts: Development of Embedded RFID tags aut iactabantur, sensitivo materiae pro conditione vigilantia et vestigia.

His innovations reflectunt latius subcinctus ad smarter, magis resiliet mechanica fasting systems capaces occurrens postulat ex altera-generation.