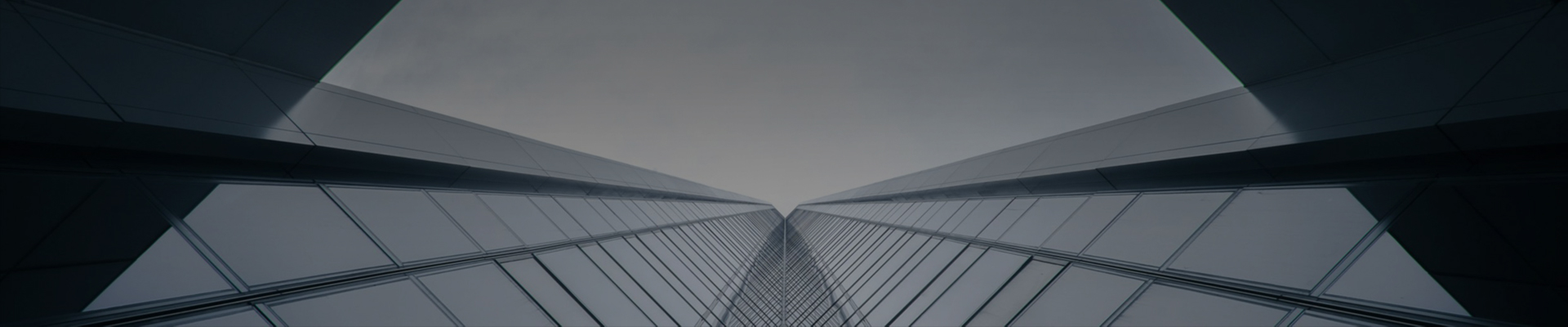

Internum retinendi annulos , Saepe despiciens in hierarchia mechanica components, sunt fundamental ad architectura de hastile-fundatur coetus. Inside a mineed ut sit intra in sulcus intra peperit et habitationi, haec annulos providere discrimine axial retention pro partibus ut gestus, anni, aut aliis onus-afferentem elementa. In utilitatem palmos aerospace, automotive, gravibus machinery, medicinae cogitationes, et dolor electronics-ullus application in axial positioning et spatium optimization sunt discrimine. Hoc articulus providet alta technica exploratio internum retinendi annulos, focusing in muneris Mechanica, materia scientia, precisione molesta, et applicationem-specifica consilio.

I. Engineering munus et axial onus imperium

Dissimilis fila fasteners aut torcular-apta components, internum retinendi annulos offer non-fila, non-permanens axial retention sine sacrificando parte accessibility. Semel sedens in machined sulcus intra peperit, haec annulos providere mechanica subsisto quod resistit interna axiali motus internum components. Illi munus per transformans radiale accentus in axial tenet vi, distribuens onus per sulcus dum servata saltum alignment.

In perficientur internum retinendi circulum cardine in pluribus interdependens variables:

-

Geometria sulcus : Width, profundum, et anguli Radii directe afficiunt accentus distributio et retention reliability.

-

Radiale Wall Press Definitio per intercessiones apta et anulum rigor determinat quam securely anulum manet sedet in scelerisque vel vibrational.

-

Axial retention onus : Calculus initus ut munus anulum crucis-section, materia cede vires, et contactus superficies regio.

Propriis ipsum requirit quod sulcus tolerances conformis ad ISO (XIII) CMVI vel asme b18.27 signa, fretus in regional exercitia et industria requisitis.

II. Material considerations et metallurgical mores

In electionem de materia ad internum retinendi annulos agitata per mechanica accentus requisita, eget nuditate et environmental conditionibus. High-perficientur annulos sunt typically fabricata a:

-

Carbon Spring Steel (Sae 1070-1090) : High cedat vires et lassitudine resistentia; Communiter calor, tractata ad optimize retention vi.

-

Immaculatam ferro (Aisi CCCII, CCCXVI) : Providet superior rumpitur resistentia cibum processus, medicinae, aut marine applications.

-

Beryllium aeris et phosphor aeris : Usus in non-magnetica aut electrically PROLIXUS environments.

-

Titanium Alloys : Maluit pondus-sensitivo, summus perficientur aerospace et biomedical cogitationes.

Post-processing vestigia ut exortum Peening, passivation, aut phosphate coating augendae lassitudine vitae, corrosio praesidium, aut friction imperium fretus in animo application.

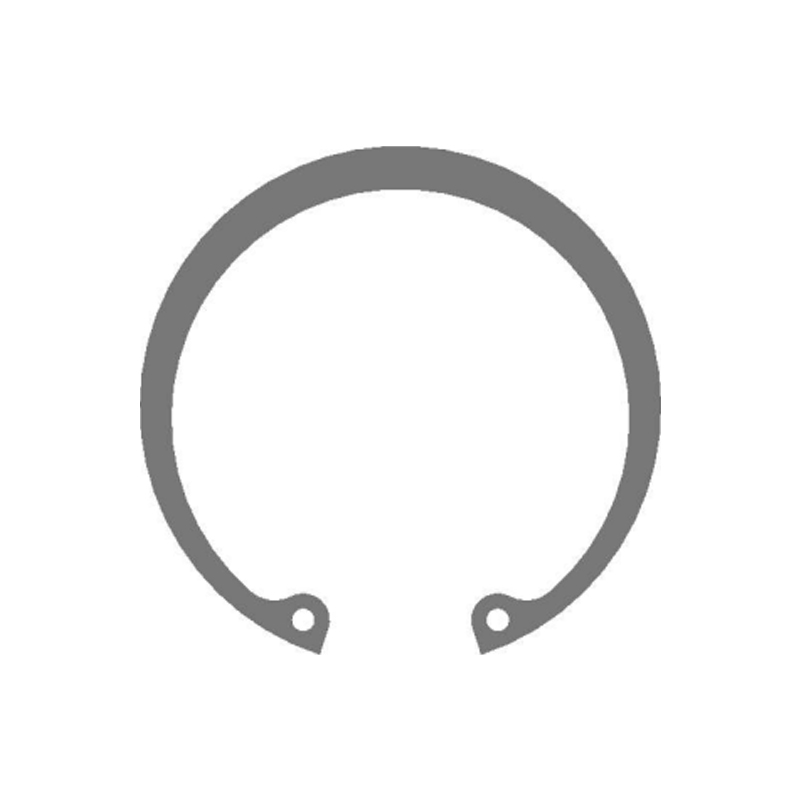

III. Precisione vestibulum et tolerantia Engineering

Vestibulum internum retinendi annulos involves summus praecisione vel coiling processus, sequitur calor curatio et superficiem condiciones. Dimensional tolerances sunt critica, praesertim in automated aut summus celeritate ecclesiam systems, ubi etiam minor deviationes potest consequuntur in insertionem defectum vel compromised retention.

Critical dimensiones includit:

-

Liberum diameter et murum crassitudine : Govere insertionem vim et sulcus idoneum.

-

Sulcus diameter et profundum compatibility : Oportet congruit anulum scriptor expanded status dum ensuring secure seating in axial onus.

-

Edge Chamfer et Burr imperium : Essential ne damnum ad adjacent components durante installation vel operationem.

Advanced qualitas potestate usura laser micrometers, optical Comparatorum, et superficiem profilometres ensures obsequio cum engineering drawings et eget reliability in ministerium.

IV. Installation Techniques et retention Optimization

Installation internum retinendi anulos typice adhibet specialized pliers, automated insertion machinis, aut pneumaticae / hydraulicis premit, fretus productionem scale et anulum geometria. Factors influentes felix installation include:

-

Radiales deformatio fines : Plus-expansion potest consequuntur in permanens plastic deformatio, reducendo vere tensio.

-

Sulcus munditia et superficies metam : Contaminants vel asperitas potest intercedere propriis vel accelerate gerunt.

-

Consuetudine Quia summus celeritas gyratorius applications, orientation ad directional accentus potest afficit diu-term retention.

In salus-discrimine systems, finitum elementum modeling (fem) adhibetur ad simulare accentus concentratione in installation et operational usus, auxilium engineers conflae sulcus geometria et materiam delectu.

V. applicationem-specifica partes et ratio integration

Internum retinendi annulos deployed trans lateque ambitus quisque imponens unique consilium challenges:

-

Automotive Transmissionibus : Oportet sustinere Cyclical loading, princeps temperaturis, et hydraulicis pressura cum maintaining situ accuracy sub vibrationis.

-

Medicinae cogitationes : Requirere biocappatible materiae et micro-tolerantia fabricam, praesertim in minime incursio instrumenta vel implantabilia cogitationes.

-

AEROSPACE Actus Systems Postulantium fortitudinem, ut-pondus componat, humilis abortio, et resistentia mechanica lassitudine in fluctuat scelerisque regiminum.

-

Consumer Electronics : Utilitas Miniatrized variants in machinationes ut Gyratorius Knobs, lens fossuring modules, quod coegi systems, prioritizing praecisione et diuturnitatem in pacto forma factors.

Praeterea, integrated designs nunc embed retinendi circulos sub-coetus ad modularity, reprehairrabitatem et pondus reductionem-a crescente trend in altus-efficientiam consilio.

VI. Defectum modis et vitae-cycle euismod

Quamvis eorum Simplicitas, internum retinendi anulos potest deficere sub aliqua conditionibus. Communis defectum modos includit:

-

Tondendas de sulcus : Ob nimia axial onus aut improprium sulcus dimensiones.

-

Lassitudine fregisset Fecit per repetita loading ultra consilium fines et microsctructurl defectus in circulum materiales.

-

Serpat et relaxationem : Praecipue in Polymer, secundum annulos sub scelerisque cycling.

-

Ruina generationem : Unde ex anulus / sulcus animum aut superficiem corrosio, potentia contaminans sensitivo systems.

Mitigation Strategies involvere materiam upgrading, amplificata superficies curatio, precise tolerancing et predictive sustentationem scheduling.

Absit a esse tantum passiva components, internum retinendi annulos involvunt convergence ex praecisione Materiae materiae ipsum et ratio integration. In partes in maintaining axial integritas in pacto coetus coetus underscores momentum rigorous consilium et vestibulum exercitia. Ut industriae systems permanere ad miniaturize et crescere in multiplicitate, in demanda ad altus-perficientur, applicationem-specifica retinendo annulos mos tantum crescere. Future Developments ut focus in dolor materials, auto-loca geometries, aut embedded sensoriis, extendendo ad capabilities huius essentiale tamen saepe underappreciated mechanica elementum.